Delphi & Tula Pioneer Software to Boost Fuel Economy

Conventional wisdom holds there are two distinct worlds in the automotive universe—the hardware-oriented gearheads who know engines, pistons and camber and the softer science engineers who design infotainment systems and the computer-oriented systems on the modern car. It’s the classic Detroit (or Tokyo or Stuttgart) vs. Silicon Valley story. Not that there isn’t plenty of crossover in a car that contains thousands of lines computer code throughout its ecosystem, but historically the engine was the province of the engineers inside a car company—and they rarely looked outside for inspiration. All that may be about to change.

Tier 1 supplier’s like Delphi are compiling CO2 reduction (or more positively, fuel economy improvement) technologies as the world’s automakers strive to meet global targets for reduced

greenhouse gas emissions. While battery electric and fuel cell electric vehicles are one path, that path is very expensive and has yet to demonstrate consumer acceptance that will guarantee its success. So in parallel suppliers and auto companies are exploring any and everything that can keep the tried and true internal combustion on a more environmentally friendly path.

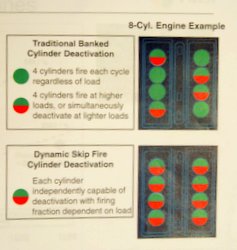

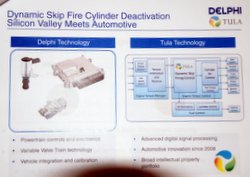

Delphi’s recent investment in Tula, a Silicon Valley software company demonstrates one of those paths. Tula has developed software algorithms that do something engineers in Detroit, Tokyo and Stuttgart had not thought possible—to shut off different cylinders independently, giving the engine power as needed in a given situation, but saving fuel by giving it only the power needed and not firing any extras cylinders. The trick is taking cylinder deactivation, which is a known technology, to a more efficient level while not sacrificing NVH (noise-vibration-harshness) usually associated with uneven firing sequences. “No one inside the OEM world would have thought of this,” emphasized Dephi’s James Zizelman, managing director, North American, Dephi Powertrain Systems.

We Drove the Demo

The Dephi-Tula solution, which Clean Fleet Report had a chance to test-drive, squeezes out those extra mpgs that every manufacturer is striving for and still delivers smooth performance. Think of it as just-in-time delivery of power, but with the added benefit of maintaining smooth operation in the complex engine environment. The end result is a system called Dynamic Skip Fire.

As Zizelman explained, in this system Dephi provides the basic hardware—powertrain controls and electronics, variable valve train technology and the vehicle integration and calibration. From Tula comes the advanced digital signal processing that makes this magic work. That magic is currently covered by 30 Tula patents with additional ones coming. In a vehicle, the result is an amazing firing pattern that looks (on a computer read-out) like the engine equivalent of a Jackson Pollock painting but with the quiet smoothness of a Monet water lily.

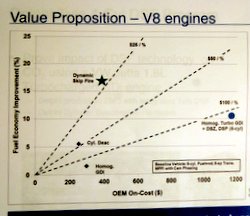

The benefit is clear. In a V-8 application Dynamic Skip Fire can deliver a steady 17 percent improvement in fuel economy—for $25 an mpg. That’s around double the fuel economy improvement of current cylinder deactivation systems, Zizelman said. He added that Delphi and Tula are now working on a four-cylinder application that will be available for demonstrations next year. In that application, which adds the system to a gasoline direct injection engine, hey expect a 10 percent fuel economy improvement—at a slightly high cost per mpg.

Delphi & Tula – Ready for the Market

Because most of the hardware is off-the-shelf, Delphi has been able to bring the integration of the new software up to “automotive grade” quality relatively quickly. Zizelman said the company expects to see Dynamic Skip Fire in production vehicles by the 2020 model year.

An additional benefit of this system might come when it is combined with something else Delphi (among other suppliers) is working on and predicts will become commonplace in the coming

model years—48-volt mild hybrid systems. As explained by Delphi’s chief technology officer Jeff Owens, “Compared to higher voltage mild hybrids, vehicles with 48-volt systems have demonstrated 70 percent of the benefit at 30 percent of the cost.” These systems, in either gasoline or diesel engines, could reduce the percentage of CO2 emissions by double digits, capture energy typically lost while braking and provide torque in the low rpm range for anemic start-stop hybrids. The 48-volt systems is particularly efficient in low speed, stop-and-go driving situations, which would ideally complement the Dynamic Skip Fire’s efficiencies at higher speeds.

Whether with Dynamic Skip Fire or 48-volt mild hybrids or a combination of both, the folks at Delphi have many ways in which the internal combustion engine will continue to remain competitive in the marketplace even as CO2 and fuel economy regulations push for higher efficiency.

Related Stories You Might Enjoy:

Top 10 Best-Selling Fuel Economy Cars

On the Way to Self-Driving Cars—Advanced Driver Assistance Technology

10 Best Engines of 2015

5 thoughts on “Silicon Valley Invades Your Engine”