Electric Vehicle Growth Is Pushing Material Needs

When most people think about easy ways to reduce their carbon footprint, one of the most common suggestions is to replace their gas-guzzling daily driver with an electric vehicle. Buying an EV is relatively easy, if a bit more expensive than an internal combustion engine car or truck, but that might not be the case in the future. How will material scarcity affect EV production moving forward?

Struggling With Semiconductor Shortages

Most of the modern technology that makes the world function relies on semiconductors. Without these materials, it’s impossible to create the chips that make everything from cellphones to EVs operate.

The chip shortage began in 2020 due to trade conflicts between the United States and China and was made worse by the COVID-19 pandemic. Most of the world’s chip manufacturing capabilities exist in Asia.

Experts estimate that the chip shortage will likely continue through 2023 and into 2024 before things start to even out. The chip shortages are now hitting the equipment used to manufacture the chips, leading to even more supply problems and making it harder to meet the growing demand.

Missing Some Basic Materials

The COVID-19 pandemic caused all sorts of things to vanish from store shelves, starting with cleaning materials and toilet paper and cycling through everything from soda to cream cheese and baby formula over the last two years. Even beer disappeared from store shelves as companies contended with an aluminum shortage.

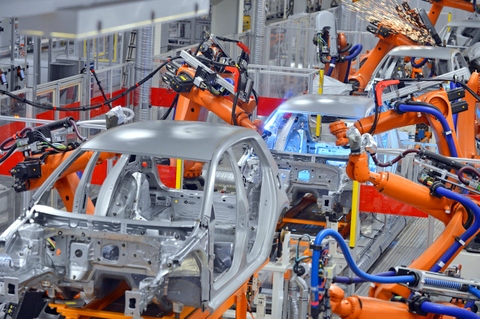

It might not seem as vital as the semiconductors used to make computer chips or the rare earth metals used to make EV batteries, but an aluminum shortage can be as impactful. Extruded aluminum is a popular choice for automotive manufacturing because it allows engineers to design robust and lightweight frames. Without aluminum, manufacturers may be forced to return to steel for their construction, which will reduce the range of EVs, making them less effective overall.

Battery Raw Material Shortages

An EV is only as good as its battery and the materials necessary to create the massive lithium-ion battery packs that power these vehicles are in short supply. It’s becoming more and more difficult to harvest and refine the manganese, nickel and lithium necessary to create these batteries.

Currently, the world’s battery production is one-tenth of what it needs to support expected EV growth over the following decades. Some in the automotive industry worry that if new solutions aren’t found, these shortages won’t just slow the adoption of EVs—they could stop it entirely.

Securing the Future of EVs

There are potential solutions on the horizon. Tesla, for example, recently applied for a permit to open a processing plant in Texas that can refine spodumene concentrate into usable lithium hydroxide for its EV batteries.

Still, there’s not currently enough supply to support the ever-increasing demand. Manufacturers will need to find new solutions if they hope to make EVs more accessible to the masses.

More EV News:

Tesla Opens New Plant; Promises New Product