Big Machines Take Different Paths to EV

Many current electric vehicle (EV) efforts focus on passenger cars. While these are the biggest contributors to transportation-related emissions, sustainability initiatives should also make room for heavy industrial equipment.

Construction machinery and other off-road vehicles account for 10% of all transportation greenhouse gas emissions—double the rail and maritime sectors combined. Thankfully, electric alternatives to conventional machines have started to come into the market. This shift stems from a few key technological improvements.

Next-Generation Batteries

Like in consumer vehicles, battery-electric alternatives are the most prominent electrification solution in heavy equipment. However, conventional EV batteries struggle to meet industrial machines’ need for long working hours in harsh operating conditions.

Modular batteries offer a few key improvements. These components are interchangeable between machines of all sizes, allowing teams to swap modules between vehicles instead of stopping work to recharge. This setup also means spare batteries can charge off-site to preserve their quality before they’re needed on the job.

Cells with higher power densities, better operating temperature ranges and faster charge times also make electrification increasingly viable. Drops in prices likewise make EVs a better alternative for budget-constrained projects.

Hydrogen Fuel Cells

Hydrogen power is another growing solution. Fuel cells are ideal for heavy machinery that can’t sit idle for long periods to recharge, as refueling takes only a few minutes. Hydrogen is also the world’s most energy-dense fuel (for its mass), allowing equipment to run longer between fueling stops.

Historically, fuel cells have been too expensive to implement in most applications, but that’s changing as research makes them cheaper and more efficient. The global energy sector has already decreased its emissions by 30% thanks to broader hydrogen power adoption.

Heavy machinery—which businesses often rent and needs additional power—is also a better fit for hydrogen than road vehicles. Consequently, it could come to industrial use cases before commercial cars.

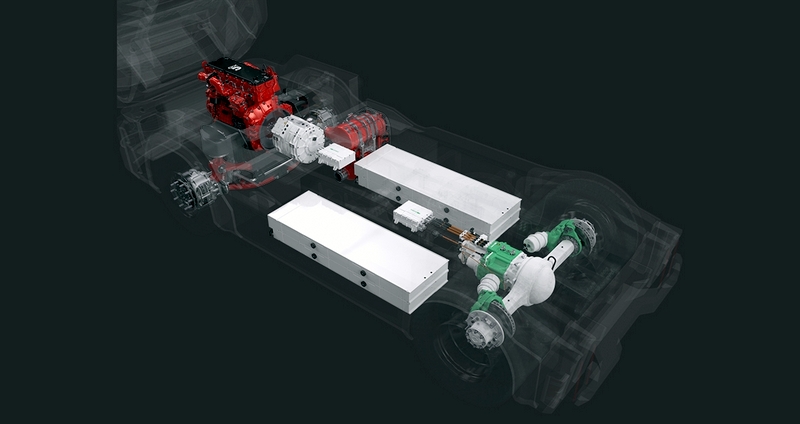

Hybrid Equipment

Hybrids are worth considering, too. While combining combustion engines and electric motors does still entail some emissions, it lets companies reduce their carbon footprint without as much investment or as significant a change in workflow. As a result, the technology is a helpful stepping stone to a fully electric future.

Businesses recognize this opportunity, too. Hybrids are the fastest-growing electric construction equipment segment, likely due to a combination of their familiarity and the fact that many manufacturers make them. Lowering emissions through these machines could help heavy industries move closer to environmental goals before improvements in batteries and fuel cells make those options more commercially viable.

Challenges Remain in Equipment Electrification

Innovations in batteries, fuel cells and hybrids are making the dream of effective electric equipment a reality. However, the sector hasn’t overcome all of its challenges yet. While costs may be the biggest obstacle in consumer applications, accessibility is a larger issue for industrial-grade machinery.

The lack of charging infrastructure near worksites makes it difficult to justify a fleet of electric machines. It takes up to eight hours to fully recharge the large EV batteries used in heavy equipment (with 240V Level 2 charging), and some heavy equipment cells may require even more time. Time is also a luxury most construction projects don’t have. Faster-charging batteries or portable fast chargers may be necessary to overcome this barrier.

Hydrogen offers a potential solution, but hydrogen fuel is even less widely available. Relatively few manufacturers produce fuel cell-powered equipment, too. The market will need to mature before companies can make significant changes to their fleets.

The Future of Heavy Equipment Is Electric

Despite such challenges, electric heavy equipment has made impressive strides. Further research, advancement and market growth will eventually pave the way for low-emissions industrial work. When that shift will occur is still uncertain, but organizations already have options to reduce their carbon footprints while maintaining productivity.

2 thoughts on “Exploring the Tech Making Heavy Equipment Electrification Possible”