Electric vehicles (EVs) are having their moment as the world moves ahead toward sustainable transportation. Ferrari’s latest evolution toward electrification is a transformative move for the brand, reflecting regulatory pressure and shifting consumer values. Central to the transition is its use of recycled aluminum in vehicle construction in the company’s first EV–the Ferrari Electtrica. The material aligns with global circularity while also meeting the demanding requirements of an all-electric supercar.

The Science and Sustainability Behind Recycled Aluminum

Recycled aluminum is ideal for high-performance automobiles due to its exceptional strength and light weight. These properties enable automakers to ensure their vehicles preserve durability and safety while reducing overall heaviness, enhancing efficiency and speed.

Recent studies show that alloying 6063 aluminum scrap with other elements—such as copper, zinc and magnesium—further strengthens the material by over 200%, demonstrating its potential for upcycling old metals into premium parts. Recycling aluminum requires 95% less energy and emits significantly less carbon dioxide (CO2) than conventional processes, thereby reducing the industry’s environmental footprint while ensuring top-tier engineering performance.

The Elettrica—Ferrari’s First Electric Supercar

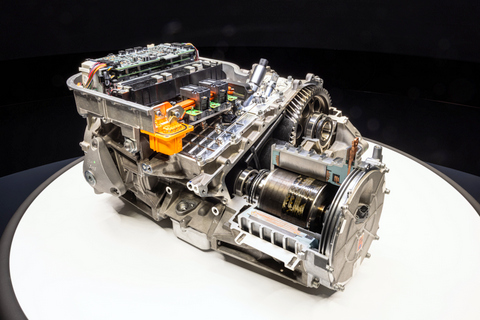

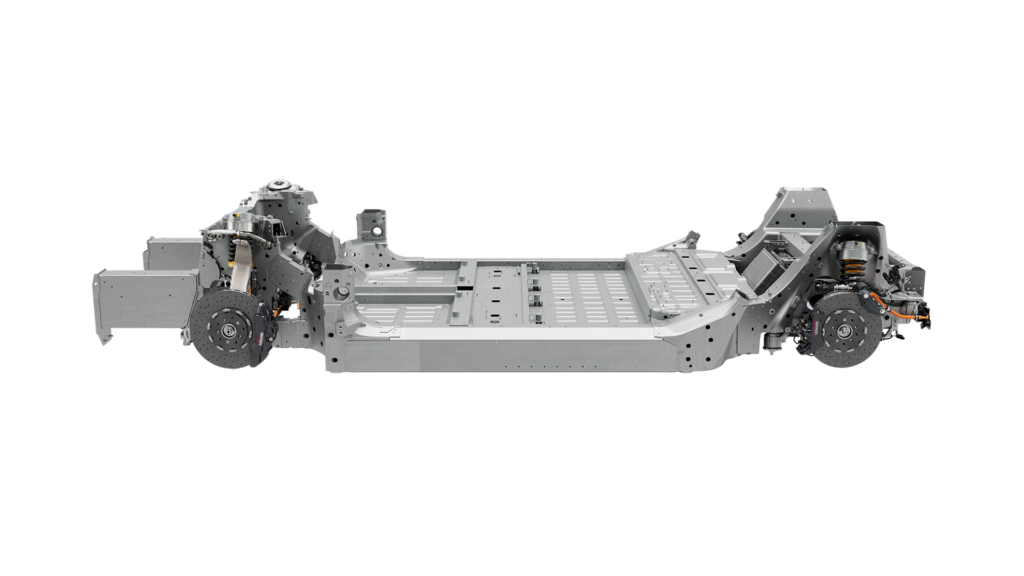

Ferrari announced its first electric vehicle—Elettrica—in October 2025. Its latest manufacturing strategy prioritizes sustainability without sacrificing performance, incorporating 75% recycled aluminum and featuring a floor-integrated, fast-charging battery to lower its center of gravity.

Achieving this feat requires rigorous crash testing and compliance with automotive standards for the use of recycled content. The automaker must source the highest-quality recycled aluminum, control alloy designs and certify materials in accordance with global sustainability standards. Because of its use of recycled aluminum, Ferrari will be able to reduce CO2 emissions by 90% compared to conventional alloys and will help save 6.7 tons of CO2 for every vehicle it builds.

The Supply Chain and Material Innovations

Amid the global transition to EVs, material sourcing and processing are now at the forefront of the innovation pipeline. The sustainable vehicle supply chain is increasingly depending on durable yet lightweight materials with superior recyclability. To drive this progress, automakers work closely with suppliers to ensure traceability and quality, leveraging cutting-edge technologies to ensure adherence to evolving industry benchmarks.

Advanced 5052 aluminum coils are among the most innovative and indispensable components of today’s EVs. With its exceptional corrosion resistance, manufacturers commonly choose it for interior and exterior applications. In particular, it maintains a pressure range of 25,000 to 31,000 psi and is highly weldable, enhancing the safety and structural integrity of the vehicles.

Implications for the EV Industry in North America

Experts forecast a 5.02% compound annual growth rate for North America’s automotive market, which is expected to increase from $590.96 billion in 2025 to $620.63 billion in 2035. A surge in EV inventory, autonomous driving technologies, digitization and connectivity, and evolving sustainability initiatives and regulations are fueling this expansion.

Ferrari’s use of recycled aluminum could accelerate a similar adoption among other U.S. and Canadian automakers, especially as both nations tighten their emissions standards, aim for circularity and incentivize greener vehicle production.

This strategy aligns with the broader shift toward sustainable mobility. Notably, consumer preferences for low-carbon automotive solutions are on the rise. A 2024 Consumer Reports survey found that fuel economy is at least somewhat important to 96% of American drivers, while 64% agree that the federal government should continue to bolster fuel-economy standards.

Setting a New Standard for Luxury and Sustainability

Ferrari is setting a new standard for luxury and sustainability with its all-electric Elettrica model. Its latest car redefines excellence with cutting-edge engineering and responsible resource use, particularly with the brand’s integration of recycled aluminum.