EVs Race for Aerodynamic Efficiency

We sometimes think that the challenges in front of a new generation of electric vehicles are all new. As the song says, we’ve been down this road before because aerodynamics are fundamental to achieving efficiency in an automobile. For EVs, that means range, but it has also been a key for speed records and efficiency.

We’ve Been Here Before

The case for streamlined cars isn’t new–for decades, mankind has searched for higher top speeds, especially in racing. Because aerodynamics are by far the most dominant force to overcome at high speeds (note that even at highway speeds, over half a car’s energy goes to pushing air away), reducing the aerodynamic drag coefficient has been key to success.

With 1.000+ horsepower (hp) Bugatti Veyron’s and Chiron’s, it’s easy to think speeds above 250 mph are a very recent achievement. Back in 1938, Mercedes-Benz reached 268.9 mph with its 616 hp W125– on a public road!

How did the Mercedes W125 beat the Veyron decades ago? You guessed it–aerodynamics. The aerodynamic power required to push through the air scales with the cube of velocity, whereas mechanical losses (like drivetrain and rolling resistance) only scale linearly with velocity. So at these speeds, aerodynamics easily accounts for more than 90% of all energy needs. In other words, with better aerodynamics you need less horsepower to reach the same speed.

The Bugatti Chiron has a drag coefficient of around 0.36. That’s not very impressive, but then again, sports cars are usually aiming for good downforce as well as style. An F1 car, for example, has a terrible drag coefficient of around 1.00, but it has enough power to overcome the drag penalty and uses downforce to deliver that power to the ground.

But when top speed is your goal, it’s a different story. The W125 had ‘just’ 616 hp (still quite significant by 1938 standards) and still was able to reach over 250 mph. How? It did it via super streamlined bodywork which featured a drag coefficient of just 0.235–more than a third more aerodynamically efficient than the Chiron!

Practical Applications of Aero

The purpose of cars is to carry people, preferably in a practical, safe and affordable way, so the constraints are quite different compared to a sports car or race car. Even at regular highway speeds, aerodynamics are by far the most important source of energy loss.

Thus it’s no surprise OEMs have been trying to cut those losses long before the breakthrough of electric cars. Aerodynamic efficiency has a direct impact on fuel consumption, something always on car makers agenda. For example, Ford experimented with different shapes for its “Probe” concept car series. The Probe V had a drag coefficient of just 0.137!

A Balancing Act

If that’s so practical for fuel efficiency, why don’t all vehicles look like the Probe? Apart from practicality, I would argue the looks are the biggest problem. You could convince me to like such a shape, since I love aerodynamics, but a car for the masses simply needs to have its own look.

Recently some attempts have been made to blend aerodynamics with traditional good looks. Examples include the Lightyear One (featuring a Cd value “below 0.20”) and the Mercedes EQXX (featuring a Cd value of 0.17). It should be noted neither are in serial production.

Although it looks nice, I think this design is “compromised.” The long, low tail, for example, is very specific (to aerodynamics). That makes it too specific to appeal to the masses, at least in the current market.

That’s why I’m so impressed with cars like the Tesla Model S Plaid and the Lucid Air, which both claim a Cd value of around 0.20. That may be higher than the Vision EQXX, but only slightly. And in my opinion, the Tesla and Lucid both still look like normal cars–they have made no design compromises and therefore have much more appeal for the typical car buyer.

Then the EV Arrives

With the arrival of electric cars, focus has shifted to the issue of range. Every kWh/m of energy consumption that can be shaved makes the car cheaper (needing fewer battery cells to go the same distance), lighter (less battery weight) and more efficient (less weight means lower rolling resistance). Since range anxiety holds back many potential buyers, aerodynamics can play a key role. The more streamlined the car, the longer the range for the same battery.

It’s not a coincidence that Tesla has an intense focus on aerodynamic efficiency–not for its cars, but even more for the Tesla Semi truck. They are not alone; newcomers like Lucid and Rivian also work hard to make surfaces as clean and streamlined as possible.

What Comes Next

What could we achieve in the future with a “no-compromise design”? That probably will depend on what you define as “no compromise design.” Some designs just take time to get used to.

GAC ENO. 146

If we stick to open wheels, then the GAC ENO. 146 concept, presented in 2019, presents a nice example of what is possible. A drag coefficient of just 0.146 is extremely low, even compared to the EQXX, and the car still looks fairly normal in terms of proportions/tail length.

Pimp my Tesla Model S Plaid

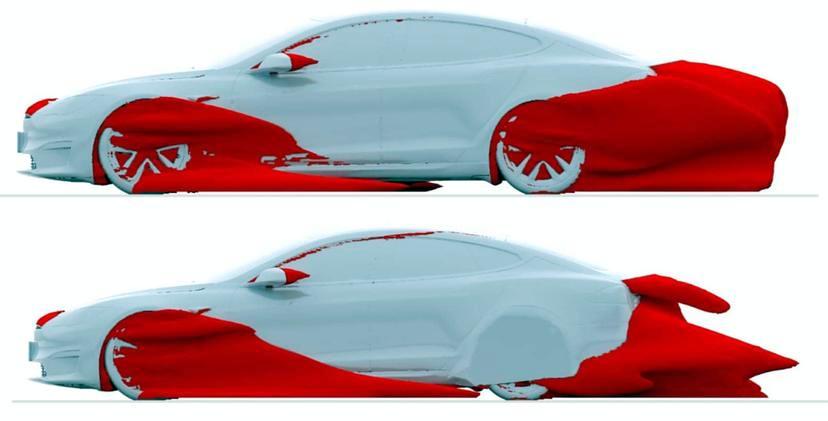

Another option is to further refine existing designs and perhaps add just a little bit of compromise. Vincent Keromnes, a leader of dynamic benchmarking at our partner A2MAC1, took a Tesla Model S Plaid (they 3D scanned the whole car down to the last detail) and then covered the rear wheels (like on the Lightyear One—or GM’s original EV1).

Vincent then ran both cars on our platform and the results couldn’t be more clear–the wake and energy loss normally caused by the rear wheels “chopping up” the air has been reduced dramatically. The impact on Cd? A 3.5% drop in drag coefficient, which is very significant in terms of aerodynamic efficiency!

Aptera

You can actually go even further and question the entire layout of modern cars–start over from clean sheet focused on the highest possible efficiency. That is exactly what Aptera did–they basically took a drop shape and added wheels to it–though three, not four.

A note on Cd values

The Cd values in the article are the official values as stated by the manufacturers. Very often, we see differences when taking these cars to the wind tunnel. Different tires, rims, ride height settings, etc., can make it harder to compare cars. Nevertheless, the relative differences in this article do tell a very interesting story of substantial progress.

Conclusion

The aerodynamic efficiency of vehicles has increased dramatically, especially with the emphasis on range for electric vehicles. Yet it feels as though we have not yet reached the limits yet. We may see even more streamlined designs in the future!

Some may look like normal cars with cleverly concealed aero tricks. Others may look downright futuristic and appeal to a more specific audience. But one thing is certain: aerodynamics will play a key role in the design of our future (electric) cars!

A Deeper Dive on Aerodynamics

Check out the airshaper.com website.

How to run your own simulation

Tech: Porsche Taycan Aerodynamics Explained

Tech: Coastdown Testing

Interview: Henrik Fisker Talks About the World’s Most Sustainable Vehicle

1 thought on “Tech: Aerodynamics Is the Key To EV Range”